This simple realisation comes from various reorganisation and restructuring projects in companies in crisis. The causes of financial difficulties usually manifest themselves long before they become acutely apparent. It is not the size of the company that is relevant, but the complexity of the products and services, as well as the customer-supplier relationships. Even a large craft business can excel through good planning or ruin itself through poor planning.

Here are two brief examples to illustrate the interrelationships.

EXAMPLE 1

Challenges

in material planning

and the consequences

In a dynamic market environment, a company experiences significant difficulties in its material planning. Although raw materials are available as commodities with good availability and flexible suppliers, material procurement is based exclusively on average consumption from the past. This approach proves to be problematic when an unexpected increase in customer demand meets a rigid, past-orientated procurement strategy. In addition, disrupted supply chains exacerbate the situation as they make it considerably more difficult to procure materials at short notice.

Special effects lead to a further increase in demand, which drives up procurement costs. The materials ratio rises by several percentage points, which has a significant impact on the company’s cost structure. Despite the cost increases in purchasing, the company is reluctant to pass on the price increase to its customers. This decision leads to a noticeable decline in liquidity.

The situation leads to a reorganisation concept that provides for extensive restructuring measures. For the owner family, this means having to liquidate assets in order to refinance the company. This could have been avoided with a modern procurement and stockpiling strategy.

EXAMPLE 2

Complexity & risks

when adapting to

customer requirements

In the second example, a company fulfils numerous special customer requests. This complicats the sales planning. The customer focus means that many parts have to be redesigned, which is not only a significant time factor, but also a challenge for the product design.

The clarification of customer requirements is lengthy and sometimes incomplete because the language of the customer is not that of the designers. In an effort to start procurement and production as quickly as possible, production orders are often released prematurely, even if the required material is still in transit. By deviating from the standard product, the second step is taken before the first.

This approach leads to a chaotic production process. BOMs are used from other project templates to speed things up and are then, of course, incomplete or incorrect. As a result, additional parts have to be procured. This not only leads to delays, but also to rescheduling and, above all, interruptions to production orders. Only during final assembly errors become apparent.

The reorganisation of the assembly sequences and the increased assembly effort lead to further complications. IT is often bent in order to get the order through production and assembly in the first place. Delivery deadlines cannot be met, which has a negative impact on customer satisfaction and the company’s image. In addition, a considerable amount of liquidity is tied up in unfinished products, which puts an additional strain on the company’s financial situation. The situation leads to an acute liquidity crisis, which necessitates a comprehensive reorganisation and restructuring of the company.

Among other things, there was a lack of modern variant management and a correspondingly adapted order fulfilment process.

The causes

These two examples show that the causes of the necessary restructuring and reorganisation sometimes go back much further than initially assumed. It is a widespread excuse that companies get into difficulties overnight. Many companies can withstand years of mismanagement before the delicate balance is disturbed. External shocks, such as market changes, are often only the trigger and not the root cause of the problems.

The core principle of management seems simple: setting goals and planning and controlling their achievement. You might think that the challenge lies in achieving over-ambitious targets. But far from it. The crux of the matter lies in planning and realisation. Why is that the case?

Planning and control processes in companies are often inadequate. The “ShiSho” principle (shit in – shit out) is not the only problem. If the process and data structures have not been set up correctly, you cannot achieve good results no matter how much effort you put in. “Catching chickens instead of mending fences” is what one plant manager called it in view of the fact that his production planners and controllers spent around 80% of their time chasing deadlines and only 20% on their actual planning tasks.

One of the main problems is a lack of transparency. Information is often difficult to access, overwhelming, contradictory or tendentious. Added to this are inadequate data structures and the poor quality of the data obtained. Key figures, rules of thumb and even estimates must be correct. The basic planning data must be up to date and well maintained.

Incorrect planning and control methods, such as a push strategy instead of a pull strategy, exacerbate the problem. Added to this are missing or misleading feedback and systemic errors. For example, when preferences for certain product or customer groups lead to inappropriate use of resources or over-complexity.

These factors lead to a chain of complications: Lack of transparency in costing, incorrect cost allocation, lack of clarity about stocks and material availability as well as a distorted evaluation of customer orders. The consequences can be serious: Long delivery times, poor adherence to delivery dates due to wide variations in lead times, high stock levels and frequent missing parts. The effects often compound each other. In the worst case, these problems can lead to a liquidity crisis or even insolvency.

It is essential to counteract the pitfalls through transparent information flows, adequate data structures and realistic planning and management.

This is the only way to ensure the effectiveness and efficiency of the company in the long term.

An economic cycle generally consists of a downturn, a stable (weak) phase, a subsequent upturn, etc. Ideally, key performance indicators announce the change from one phase to the next at an early stage. This gives you the opportunity to plan an appropriate response and thus avoid being overwhelmed by events. The company’s key figures should therefore provide high-quality information for each phase.

How to keep your company on course in the long term.

1 Do not rely solely on key financial figures, as these often only provide incomplete information about a past situation.

2 Define future-orientated key figures (e.g. order coverage), as these can be used to derive forecasts that reveal the need for action at an early stage.

3 This is supplemented by performance indicators, e.g. throughput times or adherence to deadlines. At best, they provide information about the quality of the technical and administrative processes. They are also useful for assessing whether the processes still reflect the current business model.

Where do key figures come from? How do I get them?

The key figures come from your own company or the company’s own data warehouse. At best, they are generated automatically and in a time series, whereby the presentation is a matter of taste. It is important to combine the key figures with the company’s “sticking points”. These can be, for example, bottleneck aggregates, logistics components, resources with limited availability or resources with delivery times that could even jeopardise meeting the order deadline.

When things don’t go the way you want them to …

! Form a task force: Bring experienced production managers and a responsive IT group together to resolve existing issues.

! Get an overview: It is important to have a comprehensive overview of your requirements, inventories and requirements coverages, including order information on purchase orders and production orders.

! Establish management routines and visualisations: In the short and medium term, management routines and modern dashboards are helpful to create transparency, control processes and avoid unpleasant surprises through consistent use.

! Review, revise and maintain your processes: The development of technical processes goes hand in hand with investments. It is therefore usually a matter of course to plan these processes carefully. Administrative processes, on the other hand, often simply run along and are neglected during planning. There is potential for improvement there.

! Review and optimise your data structures: You should regularly scrutinise the data structures that map products, production orders, customer and supplier relationships and improve them where necessary.

! Normally: Maintain your IT, your basic data, your planning: this may not seem important at the moment. But in the future, you will be very happy if you have a reliable database, especially when things start to go wrong.

In a dynamic environment, the future must be anticipated more quickly.

Outdated key figures, rules of thumb and pi times thumb solutions are often not enough. Years of experience based on old key figures (average values based on a 12-month average or similar) should be regarded as critical if they are not regularly checked to ensure they are up to date.

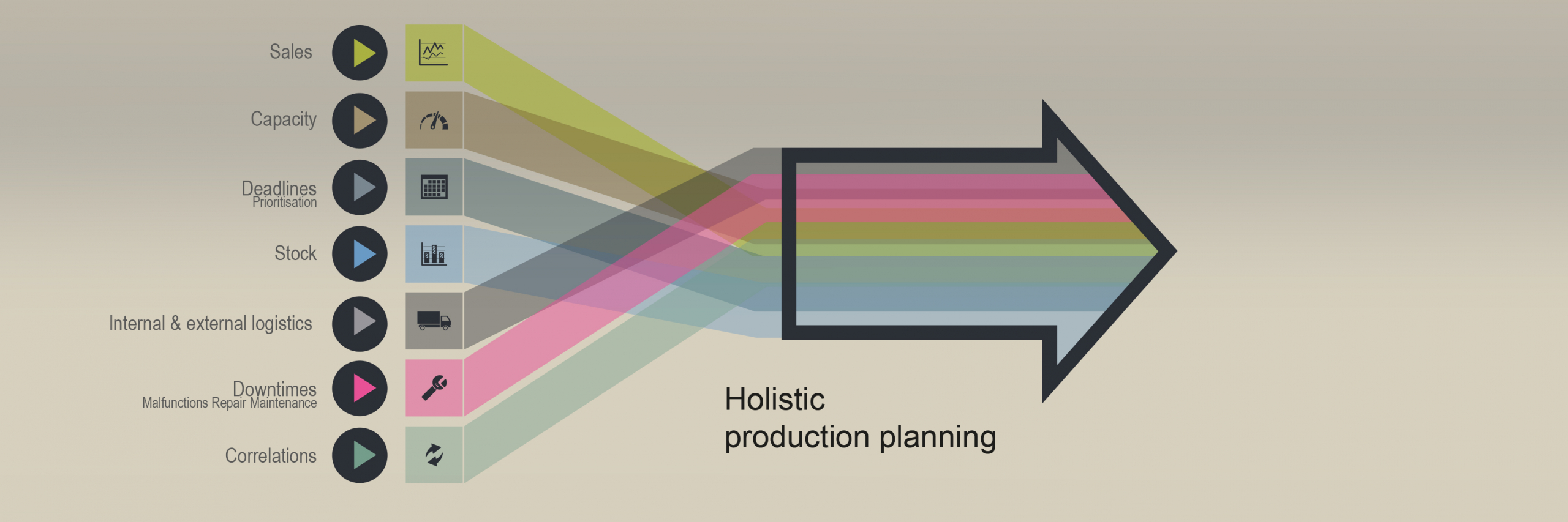

Corporate planning is part of a holistic system, namely the entire business process. In order to utilise it in a modern, flexible and realistic manner, regular feedback from all areas of the company is required. The more precisely the feedback and expectations are formulated, the better you can work with them. And only then can a holistic planning process be triggered that supports all areas of the company with transparency from the first customer contact to the delivery of the product. This is where the LEAN concept comes into play. After all, poor planning is actually the biggest waste of resources. Positive examples show how a holistic approach can drastically reduce delivery times and increase variant flexibility in a manageable way.

Are you ready …

and want to standardise your planning and optimise interfaces or do you have a really great planning idea that could do with some help?